Supply Constraints in Semiconductors

Night shift is currently closed only at VW main plant

Night shift is currently closed only at VW main plant

02/19/2022 11:02 am

The news comes as a shock to employees: Volkswagen will be eliminating night shifts at the main VW plant from April due to reduced usage. It is being told that apart from the headquarters, no other place will be affected at present. Tough conversations await. The Executive Council criticizes the purchasing policy.

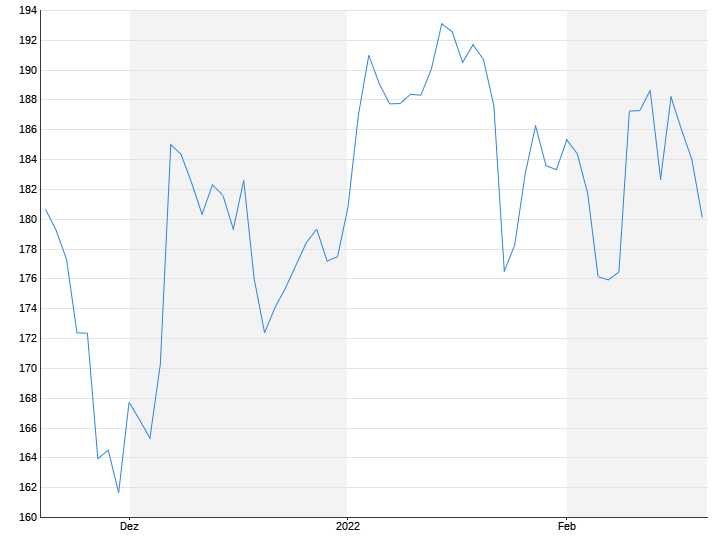

Due to a drop in production due to the chip crisis, Volkswagen does not currently plan to cut any changes outside the Wolfsburg main plant – but the Working Council continues to press for better chip purchases. “We had to close almost all places temporarily and therefore change course at the end of the year,” said Gunnar Kilian, human resources director of the German Press Agency. Plants like Emden have also been made ready for two-shift operation instead of three-shift for some time.

However, at its headquarters, VW will likely cut most night shifts from mid-April. The reason for this is the constant lack of electronics. Last year, 330,000 fewer cars were built in Wolfsburg. And there are still fewer than about 400,000 vehicles manufactured since 1958.

The Executive Council had criticized the purchasing policy of the management. Now he is demanding compensation for the loss in the shift of the affected employees. “Other vehicle-producing locations are one step ahead of Wolfsburg in the transition to e-mobility,” said Daniela Cavallo, president. “That’s why we fought to get ID.3 here to have enough options.” The electric model is to be partly manufactured in Wolfsburg from 2023 and then completely from 2024. In the current crisis at the main plant, however, the board of directors must accommodate the workforce.

Cavallo: No common problems with capacity utilization

“We have full order books — it’s not like we usually have a problem with capacity utilization,” Cavallo insisted. “But semiconductors are missing. It doesn’t go together and is hard to tolerate.” Colleagues see “that this should really work. So the company has to go ahead and take this situation into account.” A financial cushion is essential.

Killian said of the talks: “It’s not an easy discussion that we’re having right now.” However, “there is great interest on both sides in giving clarity to the workforce as soon as possible about the new shift model”. It’s not just about money, but also about the personal lives of long-time night shift colleagues, for example in coordinating with childcare or nursing. The restructuring cannot be avoided as a whole, the group human resource manager explained: “If we cannot achieve the corresponding production volume, as is currently caused by the semiconductor crisis, we must act. Because the end It’s also about maintaining competitiveness and thus job security.”

The consequences of a global recession in microchips are difficult to predict. “It’s not just a small phase that we’re talking about here,” Killian said. “We can see that we will no longer be able to use the previous shift model at the Wolfsburg location in the medium term.” Cavallo confirmed that the rapid changes should now be discussed quickly: “We are working at full speed to reach an agreement in the near future. People want to know: when will the models change and what will my work look like?” Areas adjacent to the assembly are also likely to be affected.

“Strategic, Long-Term Supply Management”

Cavallo, who sits on the supervisory board, said the lack of chips should have far-reaching consequences for the purchase at Volkswagen. “Certainly a lot has happened. We have a task force for semiconductor supply. But it’s also about building strategic, long-term supply management — not just for microchips, by the way.” Other manufacturers, for example, are already involved in chip design and thus can better secure the quantity needed from their suppliers. “It’s been recognized here – but it will take a while until everything is finally set.”

Killian pointed out that industries other than carmakers also underestimated the difficulties. VW’s Purchasing Director Murat Aksel announced more partnership-based relationships with suppliers, while CEO Herbert Diess relies on, among other things, long-term contracts with greater planning security for everyone.

Cavallo announced that how to make the working time model in car production more flexible for employees working from home will be discussed later. “We are not discussing this at present because we have to deal with many other issues first. It would not do well to bring more unrest than we have before.” The company management is probably not ready for this at the moment.

Reader. Organizer. General creator. Zombie fanatic. Alcohol advocate. Food junkie. Bacon ninja.