You enter the Immunization Center at the Palais des Congres, the convention center of the city of Montreal, and the operation is almost like a dance.

Soon the vaccine will be in your hands and you will be on your way. From a distance, it looks like a well-oiled operation in which people slip from table to table.

But it is the complex behind-the-scenes organization – including how vaccines are made, dose after dose – that makes this possible.

Camille said, “I first check every morning to see what doses we have, to make sure they match the number of appointments for the day.” Bouchard-Coulombe, deputy director of the fair. Vaccination site in the palace.

Bouchard-Coulombe is one of the many people who work behind the scenes at the Palais – and other vaccination sites in the province – to ensure that anyone who wants the vaccine gets one and no doses are wasted.

CBC Montreal followed the complex route of the mRNA vaccine in a person’s hand. This is a model that could develop if Canada makes its own vaccine Novavax, which is pending approval from Health Canada.

However, so far, the country has ordered at least 381 million doses of the COVID-19 vaccine, enough to immunize any Canadian five times.

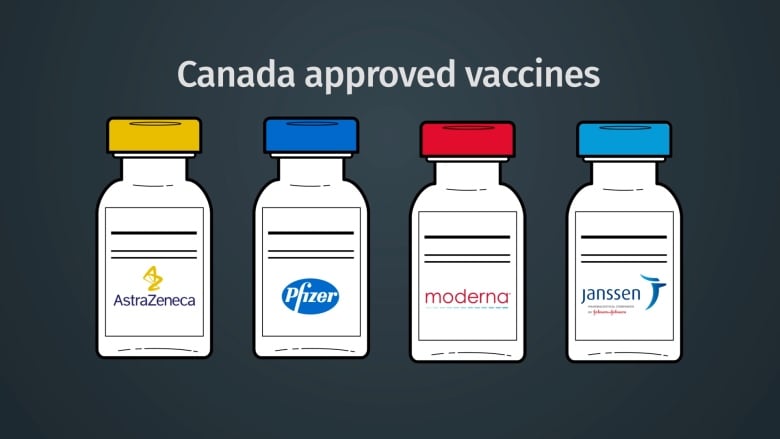

Canada currently uses four vaccines: AstraZeneca-Oxford / Covishield, manufactured in India, South Korea, and the United States; Pfizer-BioNtech made in Belgium; Made in Moderna, Switzerland and Spain; And Johnson & Johnson, made in the United States

Pfizer is by far the vaccine that will fall into the arms of most Canadians due to the amount ordered by Canada and the fact that the company has made the most frequent deliveries.

Since we have no domestic production, vaccines have to go through complex logistics routes to reach vaccination sites. These routes are managed by teams at federal, state, and local public health levels.

In Montreal, the main mass vaccination sites receive deliveries several times a week. For example, in the Palais des Congresses, it corresponds to more than 20,000 cans per week.

Employees have everything for science – cans are unpacked, heated, reorganized, ordered, filled, delivered and injected properly. And it repeats itself throughout the day, seven days a week.

While Canada’s mass vaccination campaign took a long time to form, the work has now become a proven process.

Devoted web advocate. Bacon scholar. Internet lover. Passionate twitteraholic. Unable to type with boxing gloves on. Lifelong beer fanatic.