Whether small cooling towers or water cooling: cooling solutions for SSDs are becoming more and more complex, even if it is not (yet) absolutely necessary. TeamGroup first breaks new ground with the Vapor Room Cooler with SSD. It is intended for industrial use at high ambient temperatures.

Vapor chamber theory for the first time on SSD

Vapor room coolers (also known as vapor chambers) are known from graphics cards, notebooks or older CPU cooler projects. Simply put, the principle corresponds to a flattened heat pipe in which a liquid is vaporized to be cooled by waste heat from the object. In the cold opposite direction, the vapor condenses back into liquid form and everything starts again.

The Team Group describes the cooling principle of the M.2 SSD N74V-M80 intended for industrial use in the same way that, according to the company,Vapor chamber structure designed for industrial high-performance SSD for the first timeUsed. According to the illustrations, the vapor chamber is located between a classic aluminum radiator and a thermal pad above the controller and memory chips on the M.2 module.

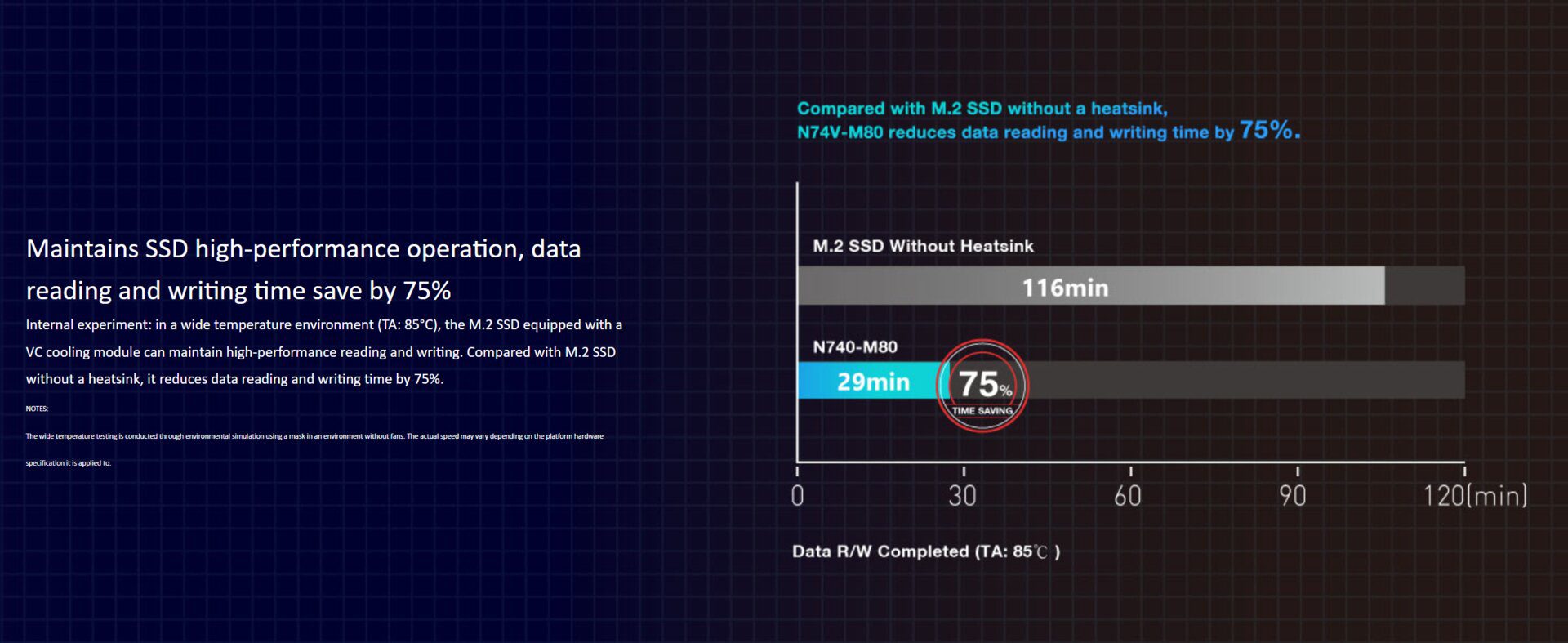

In internal tests with a simulated ambient temperature of a high 85 °C, the cooler is said to ensure that the time taken to read and write an unspecified amount of data is 75 compared to the M.2 SSD without the cooler. percentage decreases. The cooler ensures that the read and write rates remain at a high level while the performance would be throttled without the cooler. However, this information is not particularly tangible without actual details on the testing process.

The TeamGroup N74V-M80 SSD uses PCIE 3.0 x4 as an interface and achieves a maximum of 3,445 MB/s read and 2,520 MB/s write, according to the manufacturer. Equipped with 3D-TLC-NAND and an anonymous controller, 128 GB, 256 GB or 512 GB of storage capacity is available to select, Prices are not mentioned.

Internet fan. Alcohol expert. Beer ninja. Organizer. Certified tv specialist. Explorer. Social media nerd.